SINCE 1996 OSCILLATING CUTTING MACHINE FACTORY

BYT® was founded in 1996, is a leading and trusted brand in oscillating cutting machine, serves clients in 176 countries.

BYTCNC

Oscillating Cutting machine

SALES EVENT 10%OFF

Fixed Table Oscillating Knife Equipment Digital Cutter

Working Area: 1.3*2.5/1.6*2.5M/1.7*3.7M/

Machine Head:Vibrating Knife

System Adopted:Full touch screen industrial control system

CNC Vibrating Cutting Machine Details

Focus on the advertising printing industry with 30 years of manufacturing experience.

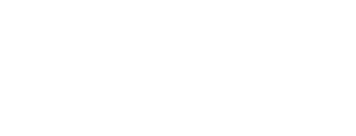

Fixed Table

Fixed platform table for reliable work output

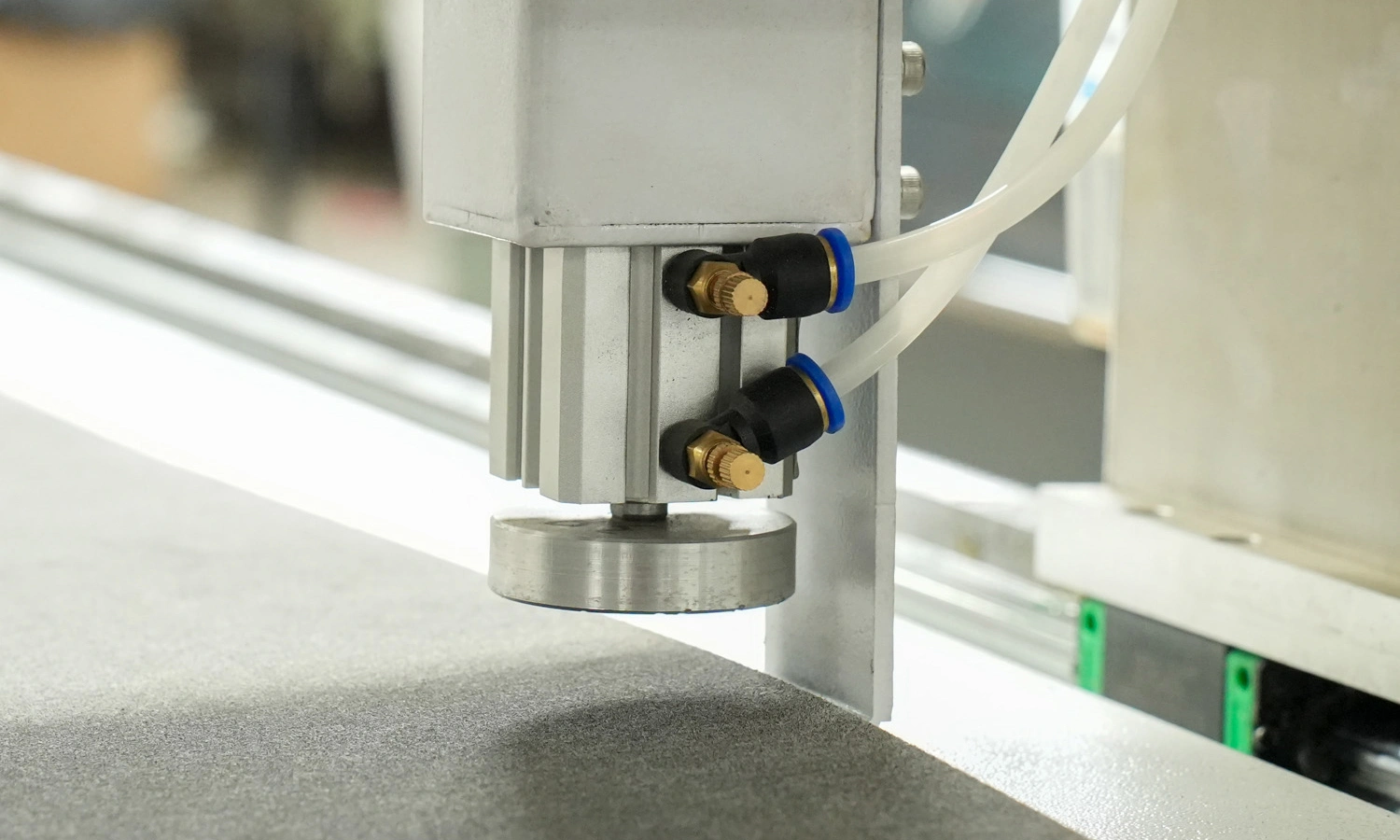

Updated System

New updated full-touch-screen industrial control system

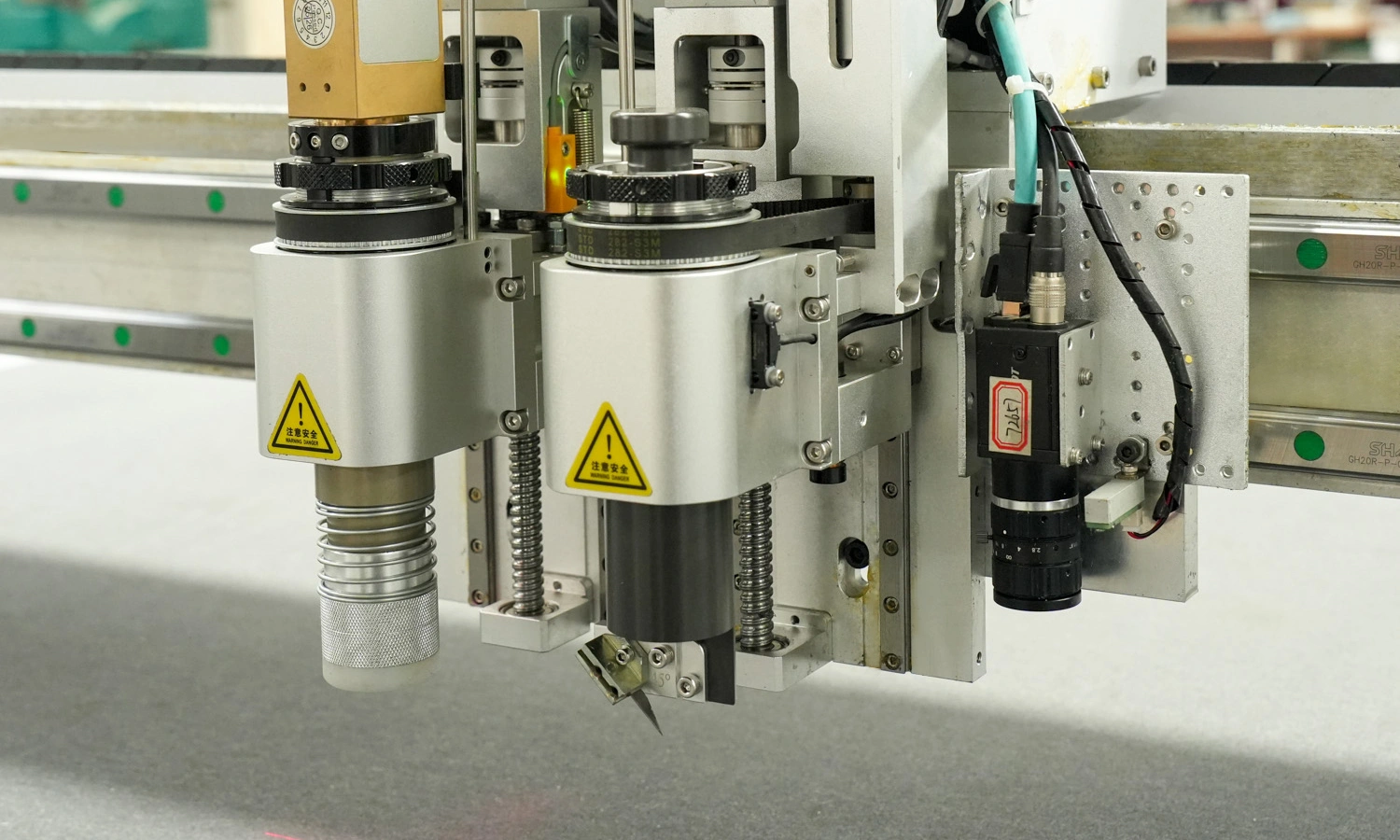

Cutting Head

Blade interchangeable by material & cutting process

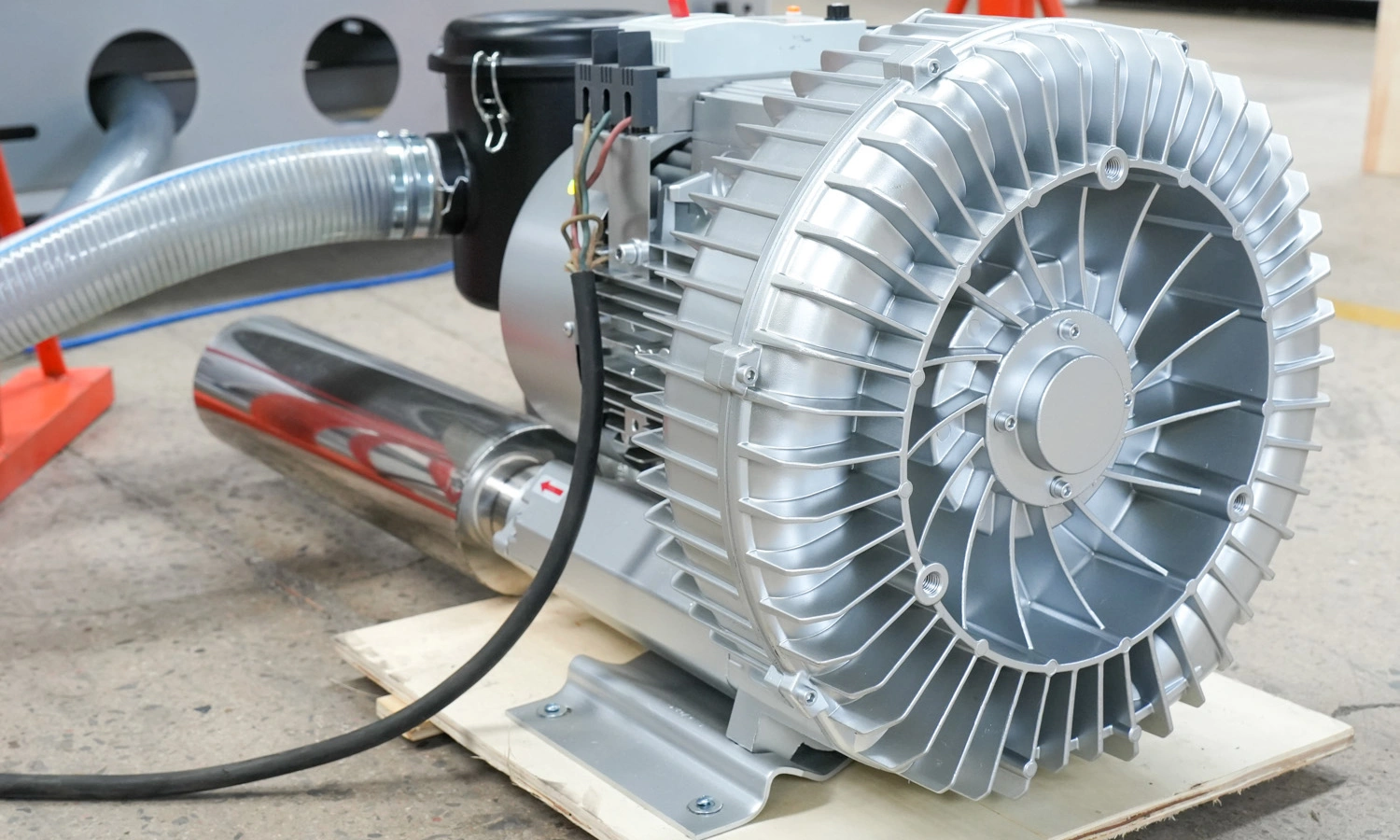

Vacuum Pump

High-power vacuum pump ensures stable material adsorption

| Specification | BZD-1325 (Fixed Table) | BZD-1625 (Fixed Table) | BZD-1737 (Fixed Table) |

|---|---|---|---|

| Equipment Model | BZD-1325 (Fixed Table) | BZD-1625 (Fixed Table) | BZD-1737 (Fixed Table) |

| Processing Range | 1300*2500mm | 1600*2500mm | 1700*3700mm |

| Feeding Height | 100mm | 100mm | 100mm |

| Worktable | Vacuum Adsorption Worktable, 3mm Aluminum Plate + 4mm Felt | ||

| System Adopted | Full Touch Screen Industrial Control System | ||

| Machine Head | Vibrating Knife | ||

| Servo Motor | XY Leadshine 750W Servo Motor | ||

| Rack | Module 2 Ground Rack | ||

| Guide Rail | Taiwan Dinghan 20 Square Guide Rail | ||

| Vacuum Pump | 7.5kW High Suction Air-Cooled Vacuum Pump | ||

| Feeding Method | Manual Feeding | Manual Feeding | Manual Feeding |

| Machine Idle Speed | 80-100m/min (single-layer fabric/leather cutting); 60-80m/min (sponge/carton cutting); 10-20m/min | ||

| Machine Volume | L3*W2*H1.6m (excluding wooden box) | L3.1*W2.2*H1.6m (excluding wooden box) | L4.2*W2.3*H1.6m (excluding wooden box) |

| Machine Weight | 700kg | 800kg | 1000kg |

Application Area

Applicable to almost all materials used in the advertising sign industry.

Paper

PVC/EVA

Acrylic

Garment fabric

Foam sponge

Leather & Fur

1 On 1 Engineer Support

We have the best after-sale service in the flatbed applicator table industry. Our 1 on 1 engineer-direct after-sale service can help you solve any kinds of problems.

- Professional Help

- 100% Problem Solved

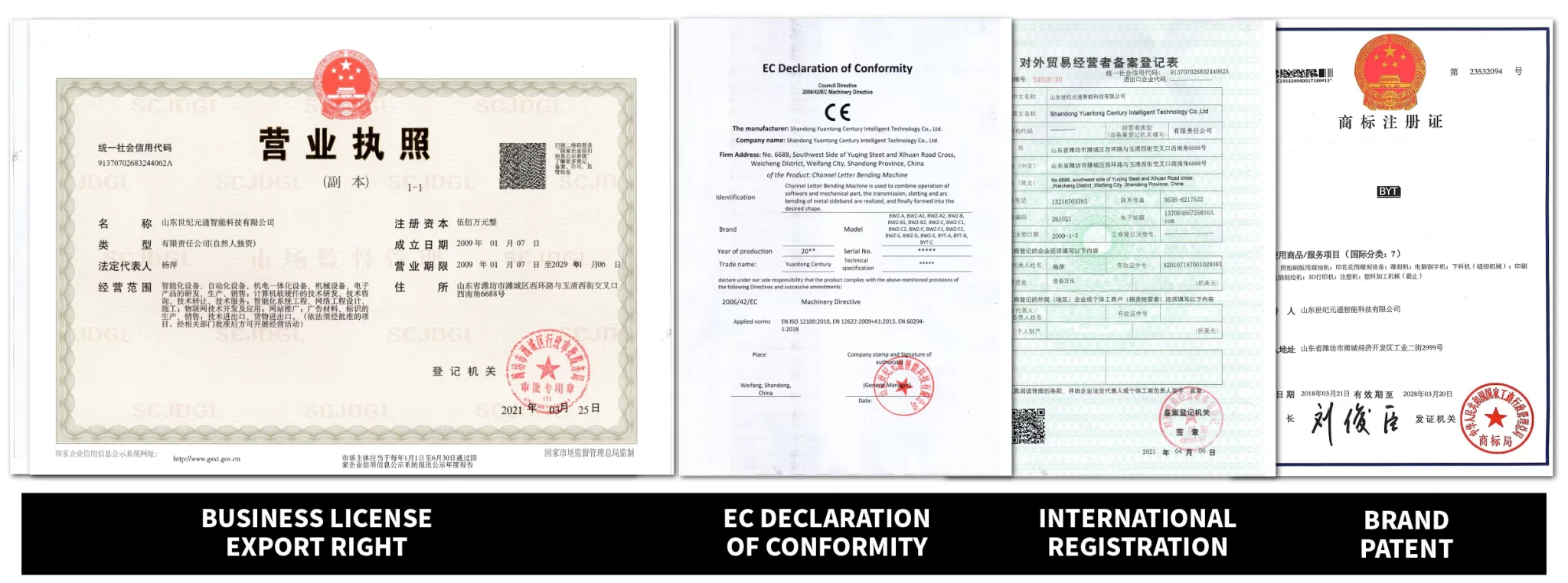

Why choose us? Oldest Factory in the Industry

Founded in 1996, we have more users and experience than our competitors.

30 Years Factory

Real Quality

Feel free to visit us anytime. Our factory is always open.

- Professional engineer service directly

- Certified with CE

- Quick-response after-sales service

- Strict quality inspection process

- Reliable product & competitive prices

BYTCNC

Contact Us To

Get Price

Contact us at any time.